This blog post covers best practices and maintenance tips for screed heads of laser-guided concrete screeds.

Maintaining the screed head is crucial for Ligchine® machines because it’s the most critical component of the screed machine. Regular maintenance of the screed head is essential. Always ensure that your machine is thoroughly cleaned; otherwise, concrete buildup on the screed head finish blade can result in an uneven surface on your concrete jobs.

Hardware checks are a vital part of screed head maintenance. Inspect every nut and bolt for looseness before and after a pour, and ensure they are securely tightened.

Bearing Maintenance:

The screed head features several bearings, located on the vibrator assembly and both ends of the auger. These bearings should be greased every time you use the machine and after cleaning it at the end of a job. Bearings are prone to wear, so keep spare bearings on hand in case of failure. Before a concrete pour, apply two pumps of grease, and one pump after the pour. After washing the machine, ensure the discharge bearing is clean. Proper cleaning is critical to prevent bearings from seizing or becoming encased in concrete. Use a pressure washer for thorough cleaning, but avoid directing water at the electronics. Protective hoods are in place to safeguard these components.

Flange bearings, due to their exposure to concrete, will need periodic replacement. To replace them, loosen the attachment bolts and seal the back side with silicone sealant to prevent concrete from seeping behind the bearing housing.

Boom Head Maintenance:

Keep the boom lubricated with a dry boom lube or a basic penetrating fluid, never grease. Grease can attract concrete dust and lead to valve wear since the boom operates similarly to a lull. Avoid allowing concrete inside the boom; maintain proper tension and regularly check the UHMW wear pads. The pads should be neither too tight nor too loose.

Head Settings:

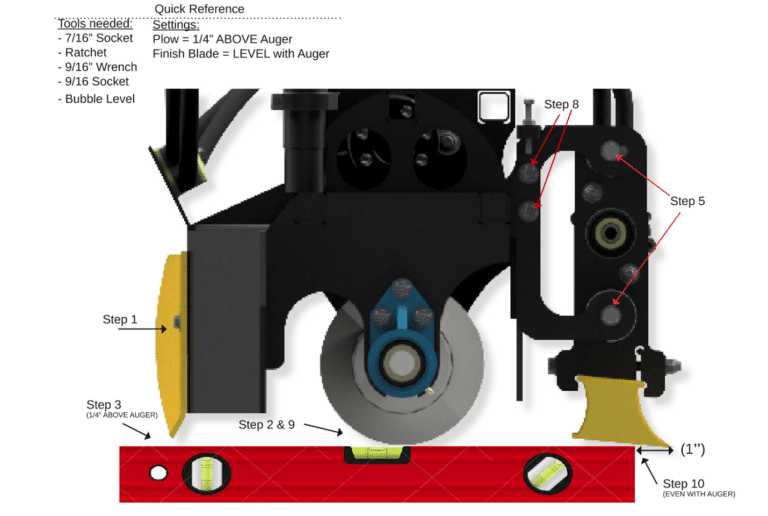

Head settings are often overlooked but crucial for optimal performance. Set the head correctly and periodically verify that the settings remain accurate. During long hauls on a trailer, the machine can shift and affect head positioning. Regularly check the settings: the plow should be ¼” above the auger, and the finish blade should be level with the auger. See diagram below from our screed head adjustment manual or call Ligchine for support +1-833-342-5544.

About Ligchine: Ligchine is a global leader in innovative and labor-saving concrete machinery. Since its founding in 2008, the company has rapidly expanded its position in the market and offers a complete line of automated concrete screeding and placing machines that service flatwork companies from small owner-operated businesses to large global concrete contractors. The company’s headquarters, engineering, and manufacturing are located in the United States. In addition to a direct sales force in the U.S., the company has an extensive network of international dealers and partners to serve customers anywhere in the world.

Media Contact:

Heather Hughes

[email protected]